Mold & Fixture

The molding department develops the metal stamping mold & fixture for the notebook computer’s LCD cover, Top Cover, and Base Cover. It is design for the aluminum stamping and aluminum-magnesium hot stamping.

The annual production capacity of molds is more than 110 sets, accounting for 50% of the development in the factory. The annual production capacity of fixtures is 400 sets, accounting for 70% of the development in the factory.

We have well experienced technicians and designers in our production lines as well as the skills in the use of software such as CAD and UG drawing design software to develop high precision moldings.

Stamping

Chongqing Datai is a subsidiary of Taiwan Tayu Group. The group has more than 40 years of professional metal stamping experience. Our product includes LCD casing, Top casing, Base casing stamping for notebook computer.

The stamping process includes aluminum and al-magnesium stamping, punching, bending, stretching, side cutting, and angle forming. We have various types of machineries to meet the necessary processing, specifications and finishings with production capacity of more than 10 million pieces.

Grind & Sandblast

The grinding process is to remove roughness and surface defects on the finished stamping workpieces by hand or machines. After the grinding process, sandblasting treatment is required to smooth out and given a high-quality texture on the surface. It also increases the adhesion during the anodize and/or coating of painting process.

The grinding and blasting facility is a working space of 6,300+ square meters. It has a professional grinding technical team, multiple equipment and advanced multi-axis automatic ABB automatic grinding machines to fully serve customer needs.

CNC

With the constant changing of trend and performance required from the market, the metal casing has evolved from simple stamping to designs that requires fully CNC (Uni-body). The Uni-body design not only enhanced the quality of the product but also requires technical skills during the CNC processing.

Datai continues investing and elevating the technical advancement with the state-of-art machines, technician recruits and training programs to be the CNC pioneer within the Western region of China and the industry.

Anodize

Our Anodize facility covers working space of 7,500+ square meters. The facility and processing equipment includes anodize automatic lines, anodize manual lines, high-gloss machine, and full laboratory for quality inspections.

The department provides anodize process for aluminum notebook casing, phone parts, auto parts, electronic cigarettes and TV frame. The processing and services include oxygen, dioxygen, gradient color treatment, T-treatment, chemical oxide film, NCT and AED.

As a responsible corporation, we fully collaborate with local government and have been approved with all environmental protection regulations and health related codes.

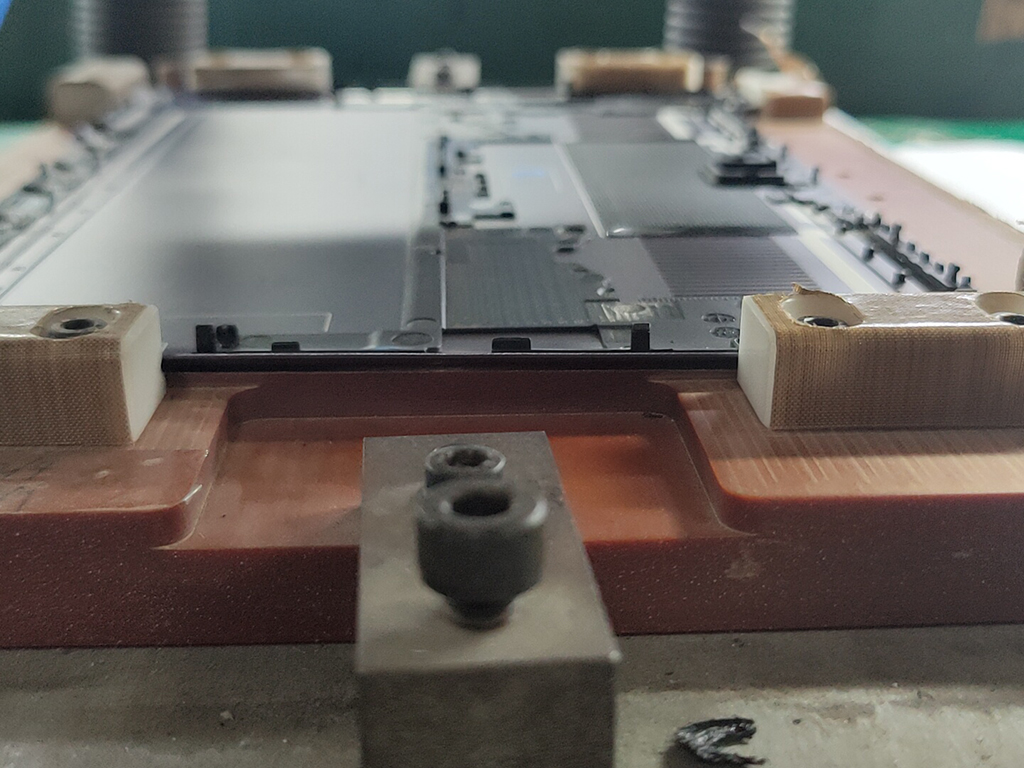

Bonding & Assembly

The assembly workshop covers an area of 6,000+ square meters.

The facility includes 15 full assembly lines with complete service of bonding, accessories pasting, auto bonding and auto inspection of measurements.

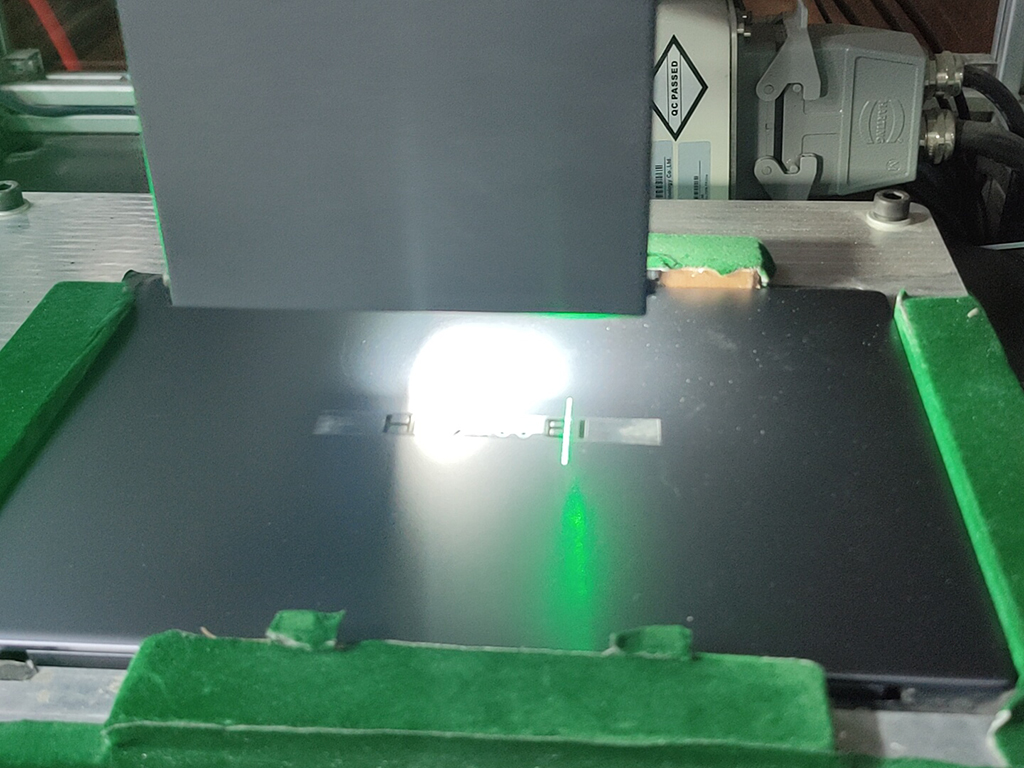

It is equipped with laser engraving, pad printing, three-axis dispensing machine, five-axis dispensing machine, hot press, CCD measuring equipment, automatic material processing line and other precision equipment.

Automation Department

The automation team is established to assist with all department’s hardware & software automation innovation and upgrades. The team will assess, evaluate a workable plan and create the fully functionable automation machine to meet production demands as well as to meet client’s expectations.

The automation innovation services include (listed but not limited) hardware & software upgrades, structure enhancement, electrical system control, PLC software, robotic arms, material upload, optical system and AOI QC inspection.

Plastic Injection Parts

Service includes mold development, injection molding, exterior painting, laser engraving, printing and assembly of large plastic products. We are an experienced quality professional providing one-stop solution from R&D, design, production, examination to assembly.